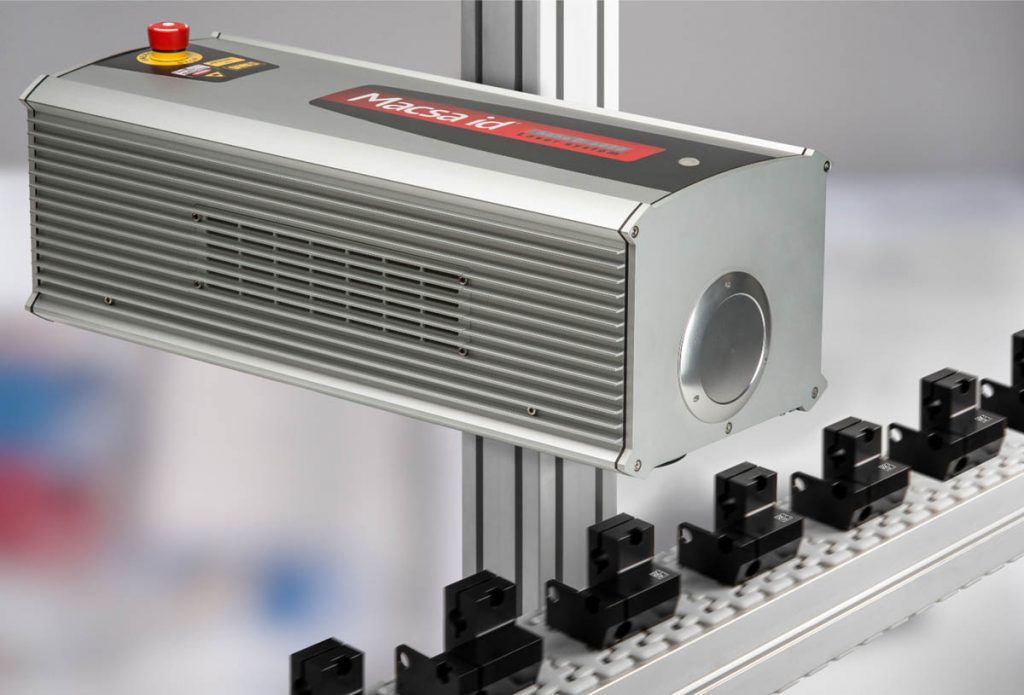

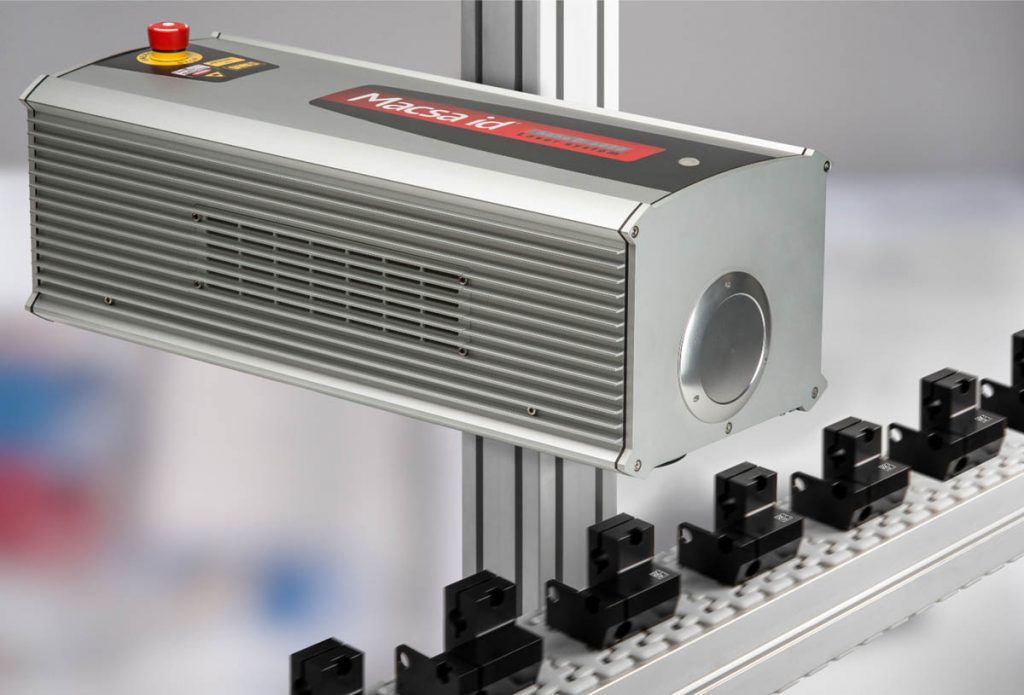

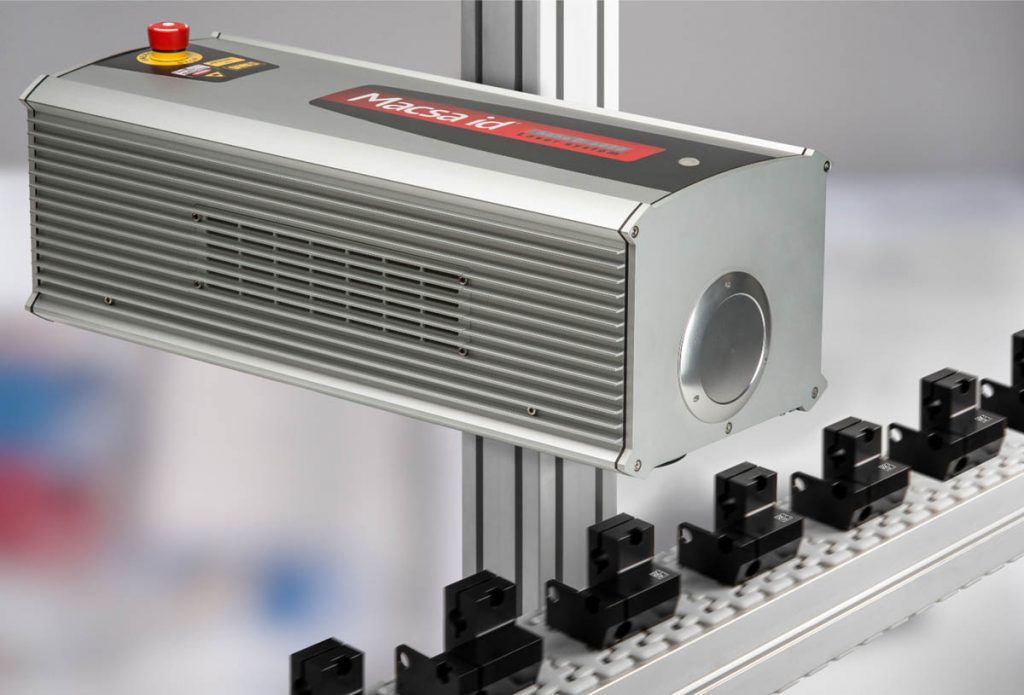

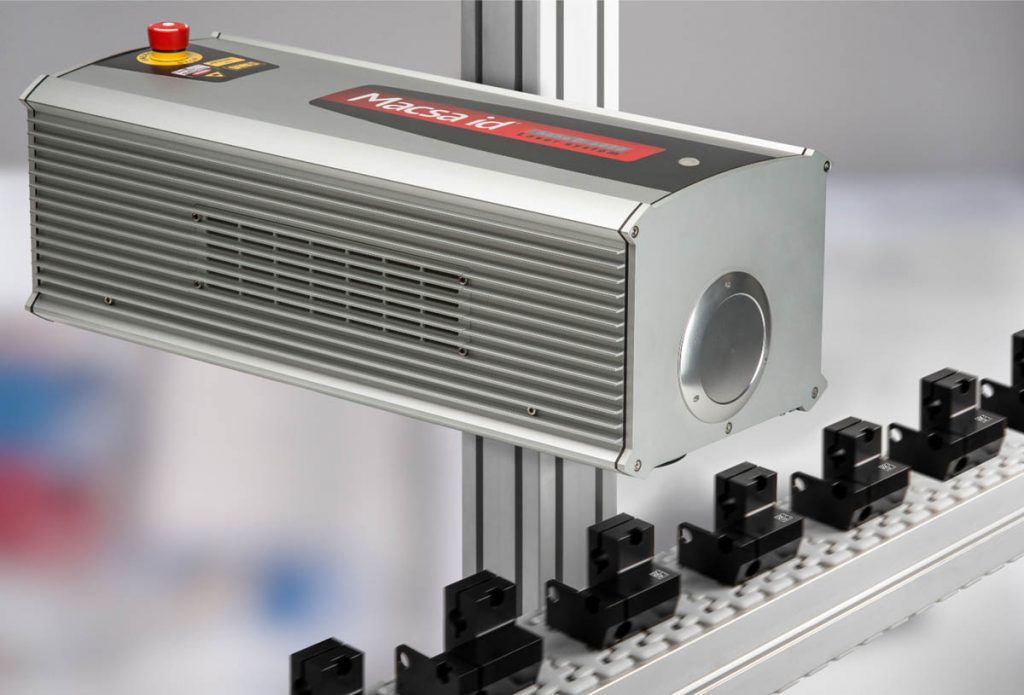

NEW SPA2 NANO UV: High precision and efficiency. The laser of the future. Contact us!

NEW SPA2 NANO UV: High precision and efficiency. The laser of the future. Contact us!

PET (Polyethylene Terephthalate) is the most common polymer in its family, primarily known as a colourless resin. It can range from semi-rigid to rigid depending on its processing, making it both lightweight and impact-resistant. These properties make PET an ideal material for liquid and food containers, particularly plastic bottles, which is its most popular application. Below, we will explain more about its uses and PET laser marking.

PET can be aluminized by evaporating a thin film of metal onto its surface, which reduces its permeability and gives it a reflective, opaque quality. This makes PET suitable for flexible food packaging applications, where durability and protection are essential.

Additionally, crystallized PET is used for packaging trays and blister packs, ideal for pre-cooked frozen meals. These trays can withstand both extremely cold temperatures for freezing and high temperatures for oven baking, making them highly versatile.

For transparent plastic bottles, CO2 laser marking is the ideal solution, providing high-quality, precise marks. For opaque materials, such as flexible film, PET laser marking can be achieved using a variety of lasers, including Fibre, Green, and UV lasers. These technologies offer flexibility and efficiency for manufacturers who need to apply durable, high-contrast markings on PET materials. Additionally, print & apply systems offer an easy-to-implement solution with minimal disruption to production lines.

If you’re looking for reliable and efficient laser coding machines, Macsa ID offers a wide range of PET laser marking solutions designed to meet your specific packaging and labeling needs.

© Copyright Macsa ID 2025. All rights reserved.