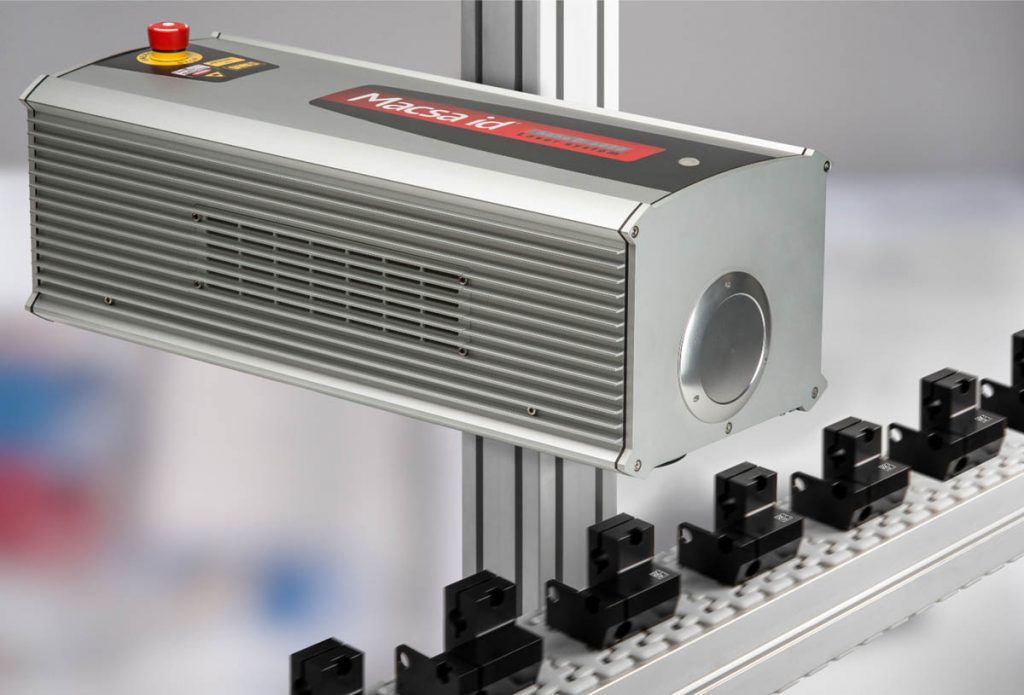

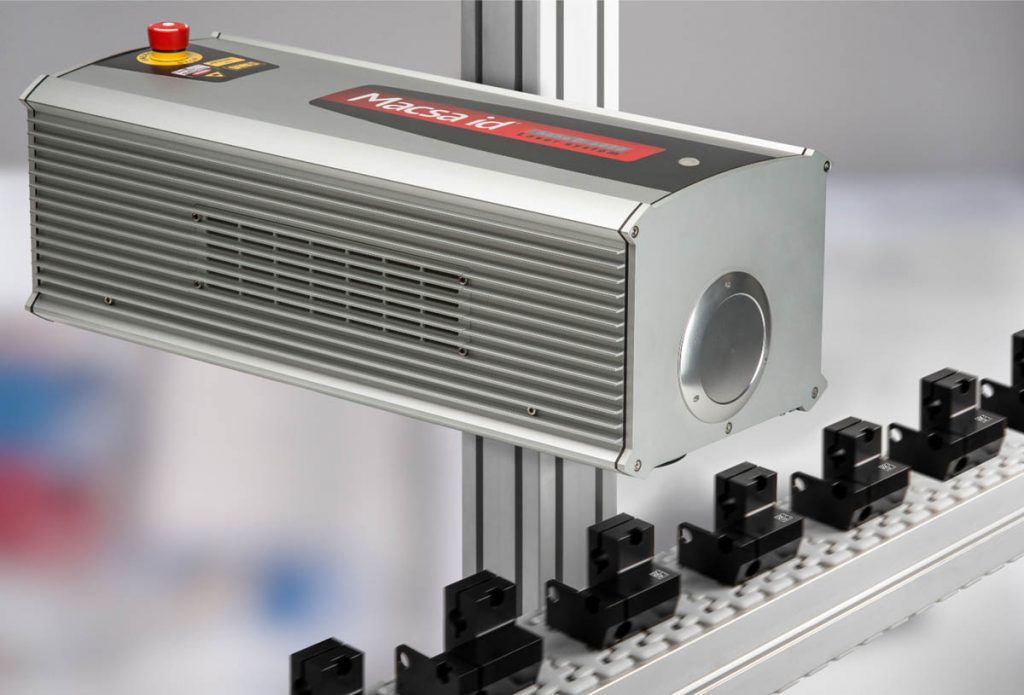

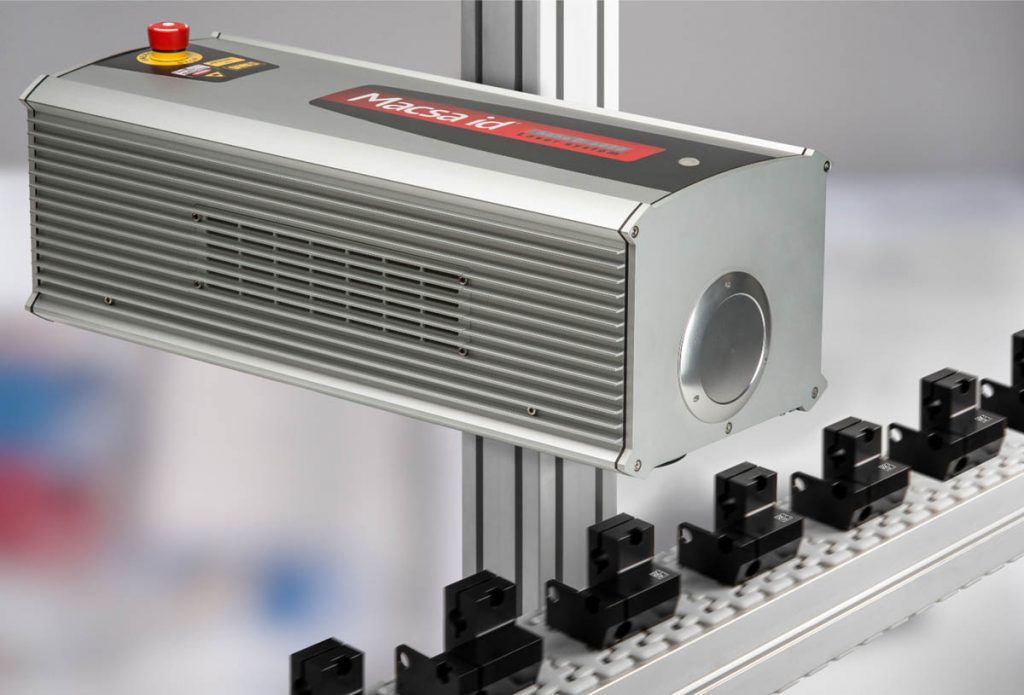

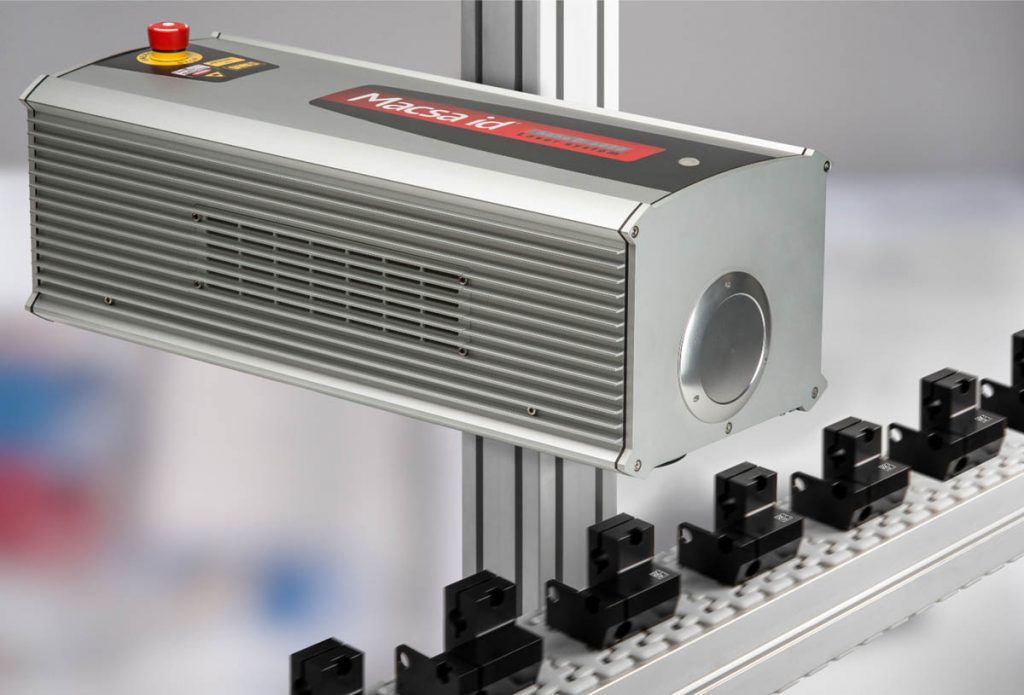

NEW SPA2 NANO UV: High precision and efficiency. The laser of the future. Contact us!

NEW SPA2 NANO UV: High precision and efficiency. The laser of the future. Contact us!

Macsa ID’s laser marking on plastic parts solutions deliver high-quality, permanent markings on a wide range of plastic materials, including ABS, polycarbonates, and nylons. Our advanced laser technologies ensure that markings on plastic components are durable, precise, and able to withstand harsh environments, making them ideal for industries like automotive, medical devices, and electronics.

Plastic is one of the most versatile materials in modern manufacturing, offering excellent mechanical and thermal properties. Plastics like ABS, polycarbonates, and nylons are widely used due to their robustness. These materials are commonly found in applications such as mechanical parts and components. Unlike high-volume items, engineering plastics are often employed for more specialized tasks. Below, we explore the uses of these materials and how plastic laser marking plays a crucial role.

A wide variety of plastic materials calls for different marking solutions. Macsa ID provides a comprehensive selection of laser technologies, including CO2, fibre, and UV lasers, to meet the diverse needs of the industry. These technologies deliver high-quality, durable markings that cater to various requirements. Whether marking industrial or commercial plastic products, our systems ensure lasting results.

ABS is a popular thermoplastic polymer used in a wide range of industries. Its amorphous structure and no true melting point make it versatile. The styrene component provides a shiny, resistant surface, while polybutadiene adds toughness. These features make ABS ideal for use in automotive parts, medical devices, keyboards, and small appliances. Thanks to its durability, ABS is a preferred choice for components that need to endure heavy usage and harsh environments.

Plastic laser marking solutions are essential for industries that rely on durable, high-precision markings on a variety of materials. Plastics, such as ABS, polycarbonates, and nylons, are used in countless applications due to their mechanical and thermal qualities. These materials are commonly used for small or low-volume applications like mechanical parts, where precise and lasting markings are crucial.

Given the vast diversity of plastic materials, there is a wide range of plastic laser marking solutions available to meet different needs. Macsa ID offers cutting-edge CO2, fibre, and UV laser technologies designed for optimal performance on plastics. These systems provide the flexibility to mark various types of plastics while ensuring clear, permanent markings.

ABS (acrylonitrile butadiene styrene) is a widely used plastic known for its toughness and impact resistance. Plastic laser marking solutions for ABS are ideal for creating sharp, resistant marks that can withstand demanding environments, making ABS a perfect choice for automotive parts, medical devices, and electronics.

Polycarbonates are strong, durable plastics used in industries like construction, telecommunications, and automotive or aeronautical manufacturing. Plastic laser marking solutions for polycarbonates ensure clear, long-lasting marks, perfect for applications like headlight lenses, reflectors, and security components.

Nylon, known for its strength and durability, is used in automotive, textiles, and food packaging industries. Macsa ID’s plastic laser marking solutions provide precise, reliable marks that enhance the traceability and durability of nylon products, including fibers, films, and molded parts.

© Copyright Macsa ID 2025. All rights reserved.