Laser coding solutions for the beverage industry

At Macsa ID, we specialize in laser coding for beverages, offering high-quality solutions that meet the demands of high-speed production lines. Our systems ensure precise, durable, and legible markings on a variety of packaging materials such as PET, glass, and aluminum.

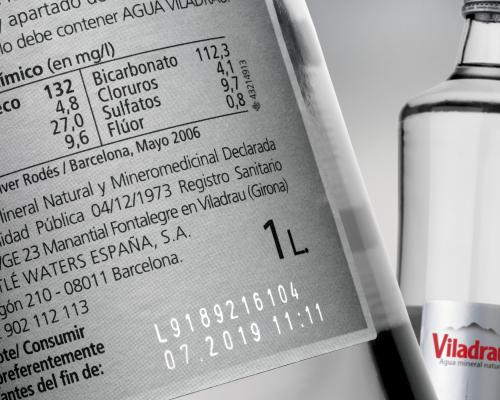

By choosing laser coding for beverages, manufacturers can improve product traceability and reduce operational costs. Whether you’re coding batch numbers, expiry dates, or QR codes, our technology is designed to handle the rigorous demands of the beverage industry.

Why laser marking is essential for the beverage industry

Laser technology is the ideal solution for coding in the beverage sector, providing high-quality, permanent markings on different packaging materials. Whether marking PET bottles, glass, or cans, Macsa ID’s laser coding solutions deliver superior performance, even in the most demanding production environments.

- Clean and Precise Marking: Our laser systems produce permanent, legible codes that withstand exposure to moisture, heat, and handling, ensuring that every bottle or can remains compliant throughout its lifecycle.

- Wide Material Compatibility: Mark glass, aluminum, cardboard, and plastic with ease using our versatile laser systems. This flexibility makes Macsa ID ideal for a range of beverage packaging formats.

- Low Maintenance Costs: Laser coding technology minimizes downtime and reduces operational costs by eliminating the need for consumables like ink, making it a cost-effective solution for high-speed lines.

Inkjet and labeling solutions for beverages

In addition to laser marking, Macsa ID offers inkjet printing and labeling systems that ensure flexibility and versatility in beverage production. These systems can print on curved and irregular surfaces such as cans, tetra packs, and bottles, making them perfect for printing batch numbers, expiry dates, and custom labels on a wide variety of materials like glass, PET, and plastic.

Specialized solutions for bottles, cans, and cartons

- Laser coding for bottles: Our laser equipment can mark the neck and base of bottles. This is particularly useful for wine and spirits manufacturers, allowing markings on bottles, corks, wooden boxes, and barrels.

- Laser marking on glass bottles: Macsa ID’s laser marking on glass bottles solutions provide high-quality, permanent markings that ensure durability and legibility even in the most demanding production environments. Our systems are designed to meet the needs of beverage manufacturers, offering precise traceability while enhancing the overall packaging quality.

- Inkjet marking for cans and cartons: Our inkjet solutions ensure fast and accurate printing on aluminum cans and carton packaging. They apply QR codes, expiry dates, and batch numbers seamlessly.

Benefits of Macsa ID’s beverage solutions

Macsa ID provides technology tailored to the beverage industry. Here’s why manufacturers choose our systems:

- High-speed production: Our solutions handle high-volume lines efficiently, maintaining consistent quality without slowing production.

- Precision and durability: Laser and inkjet systems ensure accurate and long-lasting codes that meet industry standards.

- Sustainability: Laser technology eliminates consumables, offering an environmentally friendly solution.

- Improved traceability: QR codes and batch numbers help track products from production to the end consumer.

Take your beverage coding to the next level

Macsa ID’s solutions are designed to help beverage manufacturers achieve efficient, sustainable, and precise coding. Whether you need laser, inkjet, or labeling systems, we’re here to provide the technology your production lines demand.

Contact us today to learn more or schedule a demo of our innovative coding solutions.